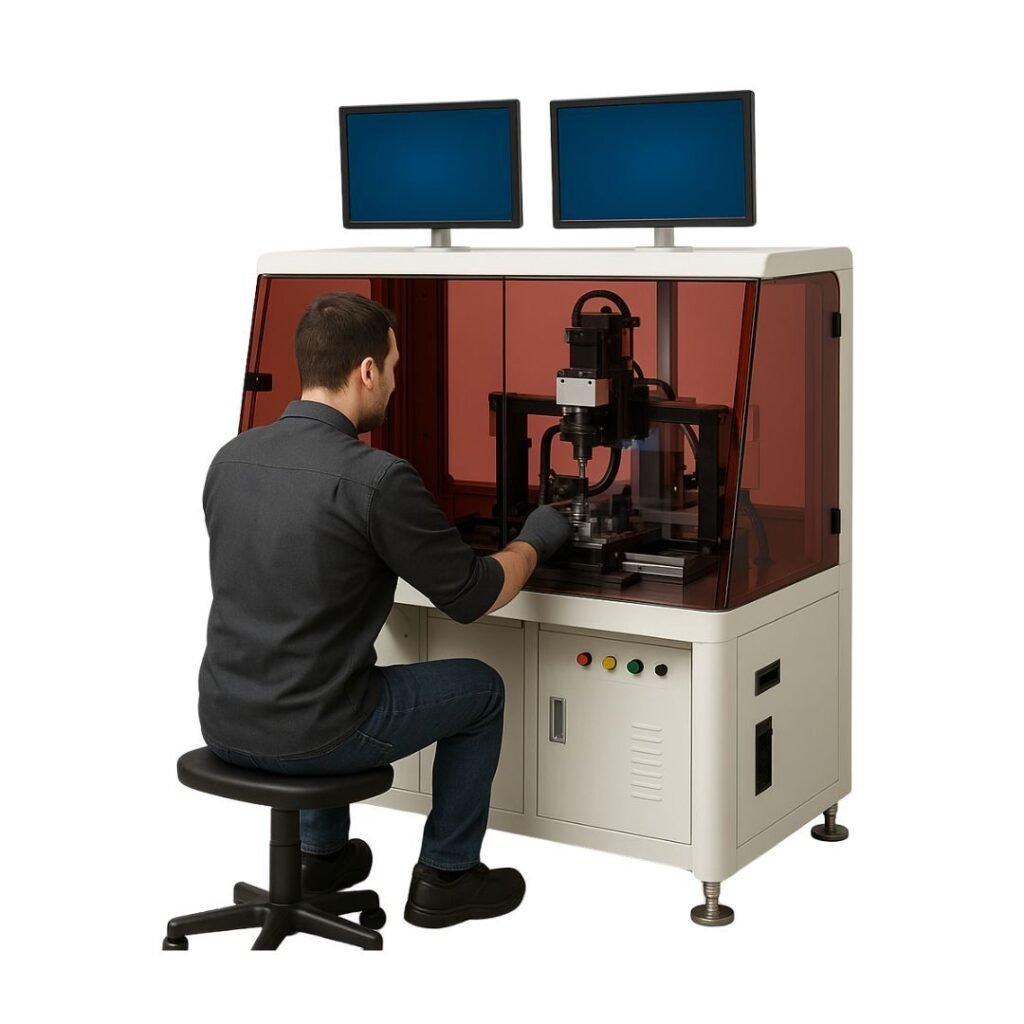

This semi-automatic inspection system is ideal for die bonding, wire bonding, or whole board inspection processes. Built with high-performance PC configuration and equipped with a set of 5D cameras, it delivers clear, accurate visual detection for bonding and wiring defects.

It detects issues such as double bonding, die offset, broken wires, scratches, sagging, and more — improving product quality and minimizing manual inspection errors. Suitable for electronics and semiconductor production lines that need a reliable, semi-automated quality control solution.

| Item | Details |

|---|---|

| Input Power | AC240V ±15%, 50Hz–60Hz |

| Compress Dry Air | 0.4–0.7 Mpa, 100 L/min |

| Size (L×W×H) | 1200mm × 900mm × 2000mm |

| Weight | About 550 kg |

| PC Configuration | FWS-610A / i9-9900K / 16G RAM / 256G SSD |

| Camera Information | 1 Set of 5D Cameras |

| Test Items | Double bonding, die offset, wire broken, scratches, wire sagging, crossing or missing wire |

Got a question or need more info? We’re just an email away — feel free to reach out anytime

yikchean.png@provisiontech.com.my

Want to improve your production with smart inspection solutions? Let’s talk. Our team is ready to understand your needs and offer the right solution — no pressure, just a helpful chat.